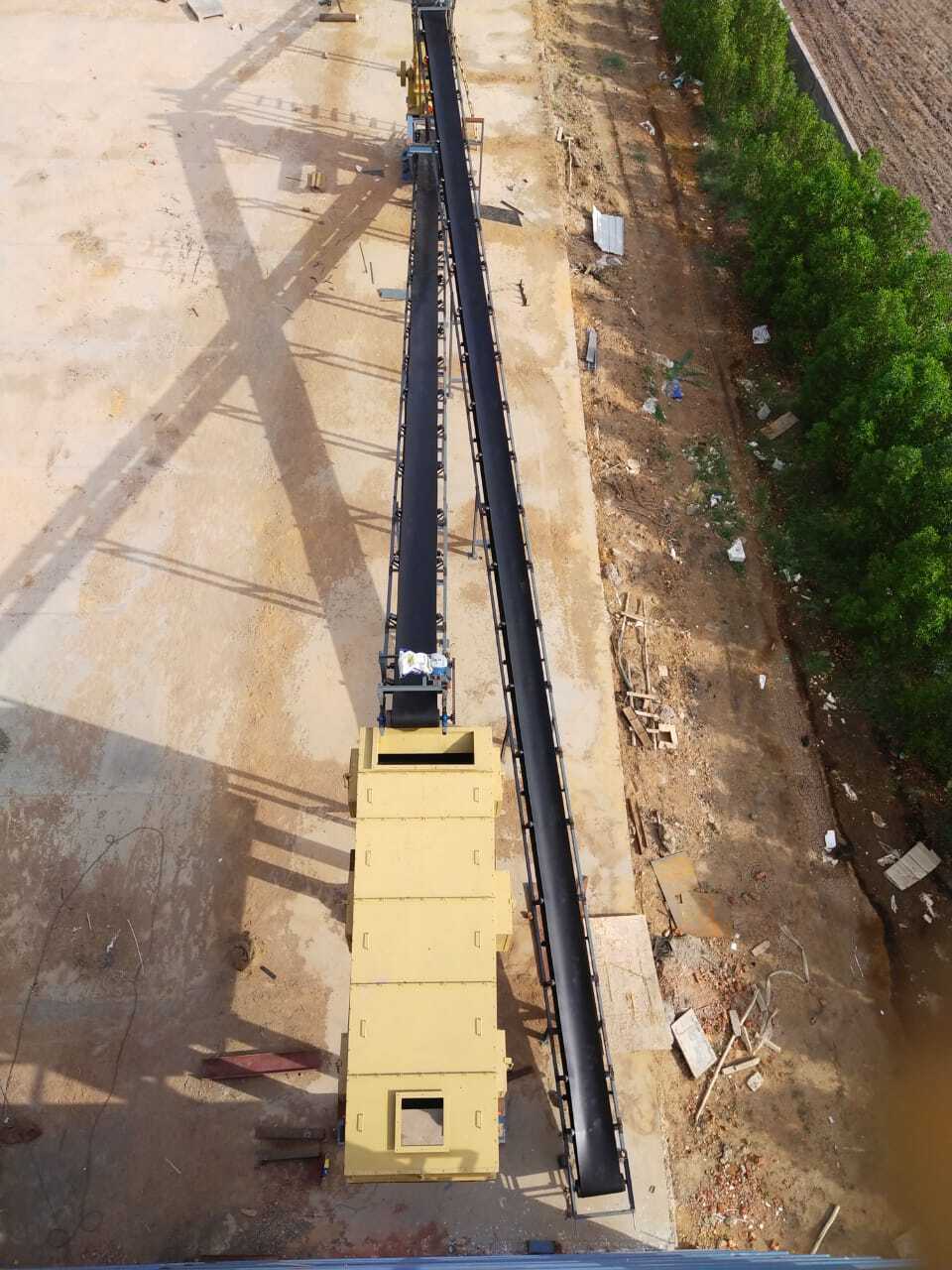

Trough Belt Conveyor

Price 300000 INR/ Unit

Trough Belt Conveyor Specification

- Power Source

- Electric motor driven

- Surface Finish

- Painted or powder coated finish

- Thickness

- Belt thickness 6 12 mm

- Features

- Simple installation, robust design, high load capacity, easy maintenance

- Belt Type

- Rubber, PVC or PU

- Material

- Mild Steel / Stainless Steel / Rubber Belt

- Type

- Trough Belt Conveyor

- Structure

- Mild Steel or Stainless Steel Structure

- Belt Conveyor

- Heavy-duty industrial belt conveyor

- Roller Conveyor

- Integrated supporting rollers

- Vertical Conveyor

- Not applicable (horizontal trough type)

- Resistant Feature

- Corrosion and wear resistant

- Load Capacity

- Up to 500 kg/meter (customizable as per requirement)

- Voltage

- 220V/380V/415V (customizable)

- Power

- 1.5 kW to 15 kW depending on length and load

- Speed

- Variable, typically 0.5 2.5 m/s

- Usage & Applications

- Bulk material handling, mining, quarry, cement, food processing

- Frame Construction

- Heavy duty channel or box section

- Maximum Incline

- Up to 18°

- Belt Joint

- Mechanical/Hot vulcanized as per requirement

- Temperature Range

- -10°C to +60°C

- Idler Type

- 3-roll troughed idlers

- Length

- Up to 100 meters or customized

- Installation

- On-site commissioning available

- Maintenance

- Low and easy maintenance requirements

- Drive Type

- Motorized with gearbox

- Customization

- Size, material and accessories as requested

- Noise Level

- <65 dB

- Trough Angle

- 20° to 35° (as per application)

- Ambient Operating Environment

- Indoor/Outdoor

- Belt Width

- 300 mm to 1500 mm (customizable)

- Safety Feature

- Emergency stop switch included

Trough Belt Conveyor Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 1 Months

- Main Export Market(s)

- Asia

About Trough Belt Conveyor

We are providing our esteemed clients Trough Belt Conveyor, which is designed to help keep loose or bulk materials in the center of the conveyor. Apart from this, we provide this belt conveyor in different specifications, in order to meet varied needs of customers. Additionally, this Trough Belt Conveyor is best for conveying loose or bulk materials, especially if the material is abrasive.

Versatile Customization for Diverse Applications

This Trough Belt Conveyor can be fully tailored to meet your specific application needs. With adjustable trough angles, variable belt widths, and a range of structures in mild or stainless steel, it efficiently transports bulk materials, even under the challenging conditions found in mining, cement, or food industries. Custom sizes and accessories ensure a perfect fit for your operational requirements.

Engineered for Reliability and Safety

Built with a heavy-duty frame and powered by reliable electric motors, this conveyor ensures stability and longevity even under demanding loads. Safety features such as an emergency stop switch, corrosion resistance, and wear-resistant construction make it suitable for continuous, safe operation in harsh industrial environments, both indoors and outdoors.

Simple Installation and Effortless Maintenance

Our trough belt conveyor features a straightforward installation process, supported by on-site commissioning services. Maintenance requirements are minimal due to the robust design and high-quality materials, enabling consistent performance and reducing downtime. The conveyor's accessible components streamline both installation and routine maintenance tasks, saving you valuable operational time.

FAQ's of Trough Belt Conveyor:

Q: How is the trough angle determined for the belt conveyor?

A: The trough angle, adjustable from 20 to 35, is selected based on the material characteristics and the specific requirements of your application to ensure optimal load carrying capacity and material retention during transportation.Q: What types of materials can this conveyor handle?

A: This conveyor is capable of handling bulk materials such as ores, aggregates, cement, grains, and food products. Its robust construction and customizable features allow it to operate efficiently in mining, quarrying, cement, and food processing industries.Q: What is the process for installation and commissioning?

A: Installation is simple and supported by on-site commissioning. Our team ensures proper setup, alignment, and testing to guarantee reliable performance from day one.Q: When should I consider maintenance for the conveyor, and how easy is it?

A: Routine maintenance is low and primarily involves periodic inspection of the idlers, belt, and gear system. The heavy-duty design and accessible construction allow for quick and easy maintenance, reducing downtime.Q: Where can this conveyor be installed and operated?

A: The trough belt conveyor is designed for both indoor and outdoor environments, thanks to its corrosion and wear-resistant properties, and adaptable construction suitable for various site conditions.Q: What benefits does the emergency stop switch provide?

A: The integrated emergency stop switch enhances operator safety by allowing immediate shutdown of the conveyor in case of emergencies or hazards, minimizing potential accidents.Q: How can the conveyor be customized for my application?

A: Several aspects can be tailored, including trough angle, belt width and length, belt type (rubber, PVC, PU), structure material, load capacity, voltage, and finish. Accessories and frame modifications are also available to meet unique operational and site requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Belt Conveyor Category

Rubber Belt Conveyor

Price 450000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Voltage : 220440 V

Vertical Conveyor : Other, Not Included

Belt Conveyor : Other, Included

Resistant Feature : Other, Heat Resistant, Oil Resistant, Wear Resistant

Industrial Rubber Belt Conveyor

Price 150000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220V / 380V / Customized

Vertical Conveyor : Other, No

Belt Conveyor : Other, Yes

Resistant Feature : Other, Heat Resistant, Oil Resistant, Fire Resistant, Wear Resistant

PVC Belt Conveyor

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220440 V

Vertical Conveyor : Other, No

Belt Conveyor : Other, Yes

Resistant Feature : Other, Corrosion Resistant, Heat Resistant

|

STERLING ENGINEERING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry